Understanding the Difference Between Desoldering and Soldering

There is a big difference between desoldering and soldering, and it’s important to understand the differences before beginning your next project. Desoldering is the process of removing solder from a joint, while soldering is attaching solder to a joint. Desoldering requires special equipment like a desoldering pump, while soldering can be done with a simple soldering iron. In general, desoldering is used to repair or clean up mistakes, while soldering is used to assemble or join pieces together. Knowing the difference between these two techniques will help you achieve better results in your projects.

Almost everything in life has a learning curve, and soldering and desoldering are no exceptions. Nevertheless, these are two essential skills for any electronics hobbyist or professional. The difference between the two may seem subtle to the uninitiated, but there is a significant distinction between these techniques. Knowing when and how to use them can differentiate between a successful solder joint and a frustrating mess. Let’s take a closer look at these two processes and see what makes them different.

The essential guide to soldering and desoldering

Desoldering is the process of removing solder from a connection to allow for component changes or repairs. Soldering is the process of creating a permanent electrical connection between two or more components by melting and flowing solder to make the joint. Desoldering methods include heat, vacuum, wick, and braid. Understanding how each tool works will help you choose the best method for specific applications.

Heat is the most common desoldering method and can be effective when removing one component at a time. Although many tools exist that use heat as the primary source of desoldering, using a soldering gun with a clean tip works best because it will not leave excess solder on the circuit board.

However, solder can quickly build up on a hot tip and transfer to sensitive components before removing the heat source. To avoid this problem, always give the iron enough time to clean off the old solder with a fresh coating of rosin before use.

How to use hot air desoldering station

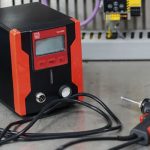

When it comes to electronics, a hot air desoldering station is one of the most useful tools you can have. This blog post will explore how to use a hot air desoldering station and why it’s an important part of any DIYer toolkit.

You’ll need: A soldering iron, solder wire, a heat sink or chisel tip on your soldering iron (make sure the tip doesn’t come in contact with anything directly), some desolder pump fluid for cleaning out excess solder from underneath components, as well as some flux-core solder if you’re going to be resoldering something back onto the board after removing it. Of course, you want all these things close to your work area.

The best way to avoid damaging delicate components during this process is by using the right size nozzle for the job at hand. The wrong sized nozzle could result in too much or not enough heat is applied, which could damage your electronics. In addition, it’s important that you read all of your equipment’s instructions before use, as well as follow any safety precautions outlined there. Finally, when finished with your project, make sure to clean up any mess left behind!